Since 1993, our Ultimate Trainer Pitching Machines have been the most reliable and advanced baseball and softball pitching machine available. The versatility of our Ultimate Trainer 3000 and our newest Ultimate Trainer 3020 enable our customers to generate more money from each batting station while decreasing the need for larger cages.

Also check out our indoor and outdoor Range-Pro Batting Cages and Range-Pro Retrieval Systems.

ULTIMATE TRAINER CAGES COST LESS AND MAKE MORE MONEY!

ULTIMATE TRAINER CAGES COST LESS AND MAKE MORE MONEY!

The Ultimate Trainer style pitching machines have proven themselves to generate three to five times the revenue as the old single speed stations. With every station available to every type of batter that comes in, the size of the batting cage can be reduced, lowering your initial investment. Today’s 3 to 6 station Ultimate Trainer Batting Cages generate more money than the 6 to 9 station cages with a single speed in each cage. Considering that at least 65% of your initial cost is building the cage, reducing the cage by just one station will cover the cost to make all the remaining stations Baseball and Softball Ultimate Trainer stations. Increased revenue and decreased capital costs make the Ultimate Trainer a simple choice for successful cage operators.

Here are just a few of the advantages of choosing the Ultimate Trainer 3000 and how it helps you make more money with less invested:

Superior Accuracy: The Ultimate Trainer computer checks for proper pitch speed and height every time a speed is selected. This makes sure it throws a strike every time! The Ultimate Trainer automatically makes small day to day adjustments to throw perfect strikes regardless of temperature, humidity, or motor wear.

Adjustability: Allows the batter to change the height of the pitch to match where they want the ball in the strike zone. Automatically resets to center strike zone after the cycle ends.

Improved Customer Satisfaction: The batters gets the speed they want and where they want – faster and without any assistance from the cage management. Less waiting means more use per visit and more return visits.

Reduced Repair Time: When the self diagnostics cannot repair the problem, the machine automatically calls for maintenance and the LCD display tells your staff where to look to fix the problem, which speeds up repairs.

The 48-SPEED UT3020 ULTIMATE TRAINER BASEBALL & SOFTBALL PITCHING MACHINE USES A TOUCH-SCREEN KIOSK AT THE BATTER’S STATION.

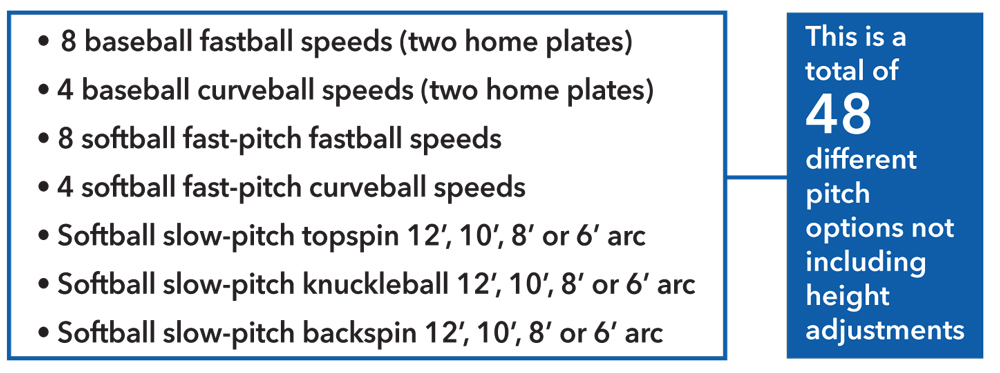

The UT3020 Ultimate Trainer pitching machine allows each batter to choose from 48 different pitch speeds and types of pitches. Increasing the option from eight pitches (with our UT3000 model) to 48 different baseball/softball options lets you supply the exact pitch a batter will want. Sinkers, curveballs, high arc, low arc, and a wide variety of pitch heights give the batter 337 total options. The touch screen controls on the kiosk at the batting station makes it easy for the batter to make adjustments.

The UT3020 Ultimate Trainer pitching machine allows each batter to choose from 48 different pitch speeds and types of pitches. Increasing the option from eight pitches (with our UT3000 model) to 48 different baseball/softball options lets you supply the exact pitch a batter will want. Sinkers, curveballs, high arc, low arc, and a wide variety of pitch heights give the batter 337 total options. The touch screen controls on the kiosk at the batting station makes it easy for the batter to make adjustments.

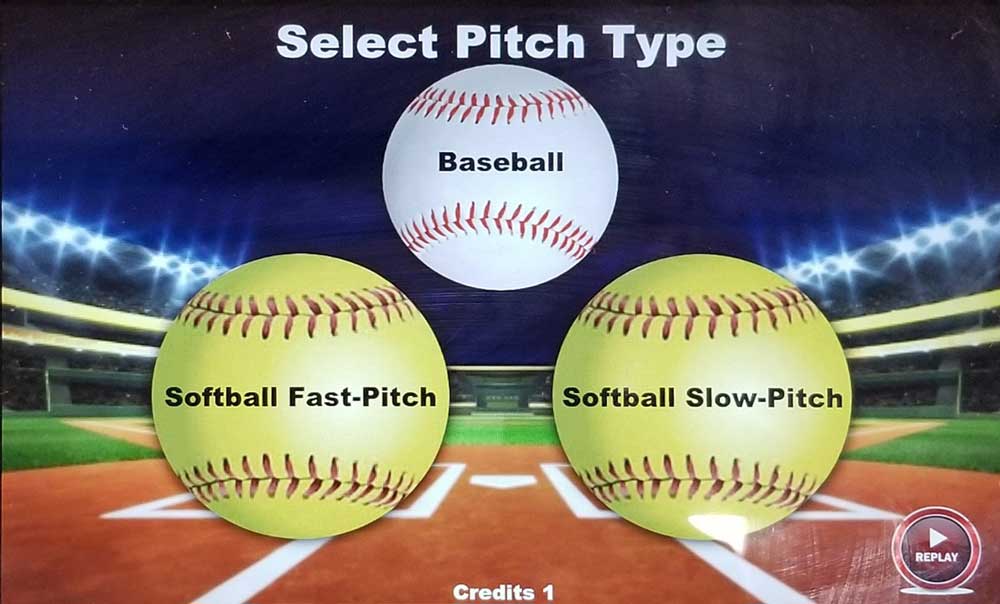

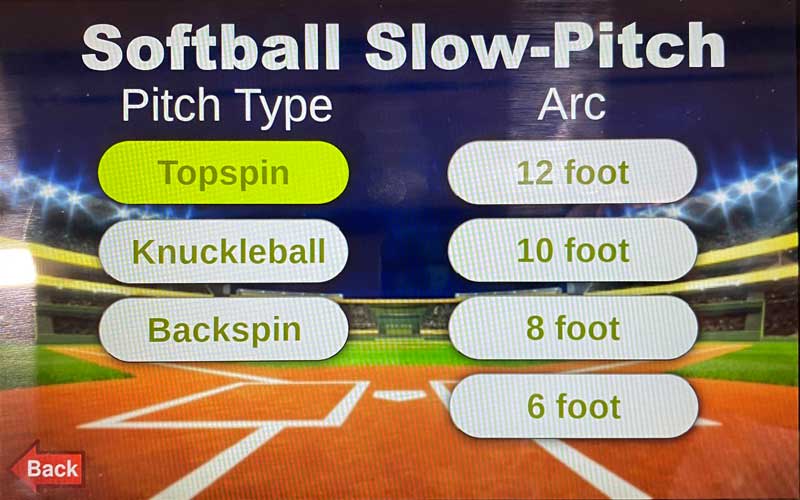

After swiping a card to play, the next screen will ask which type of pitch: Baseball, Fast-Pitch Softball or Slow-Pitch Softball

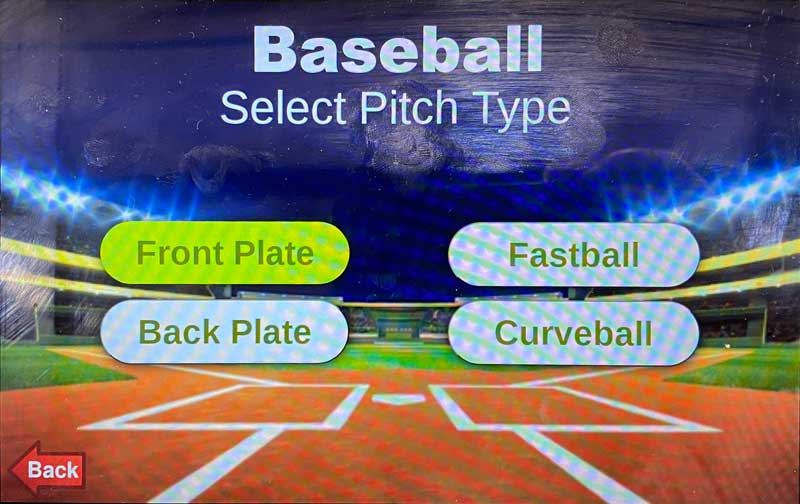

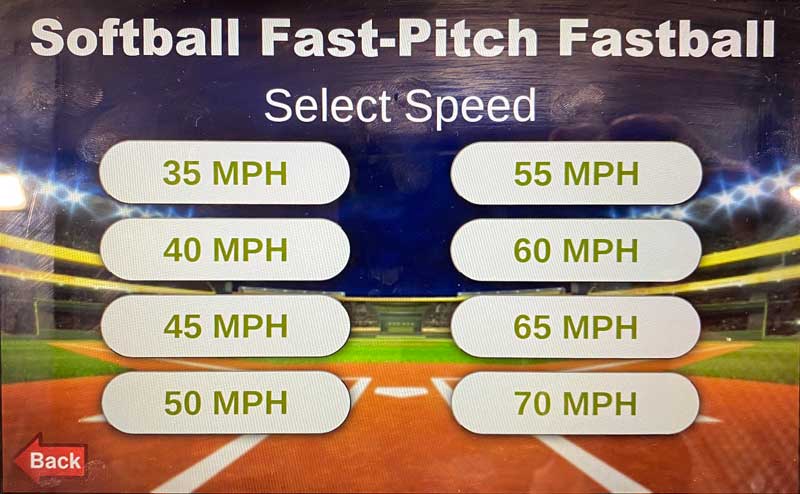

The next screen (one of three) will ask for a pitch speed and type preference based on selection from previous screen:

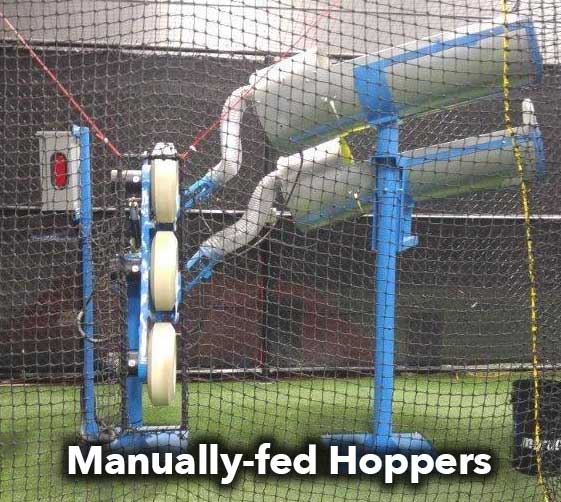

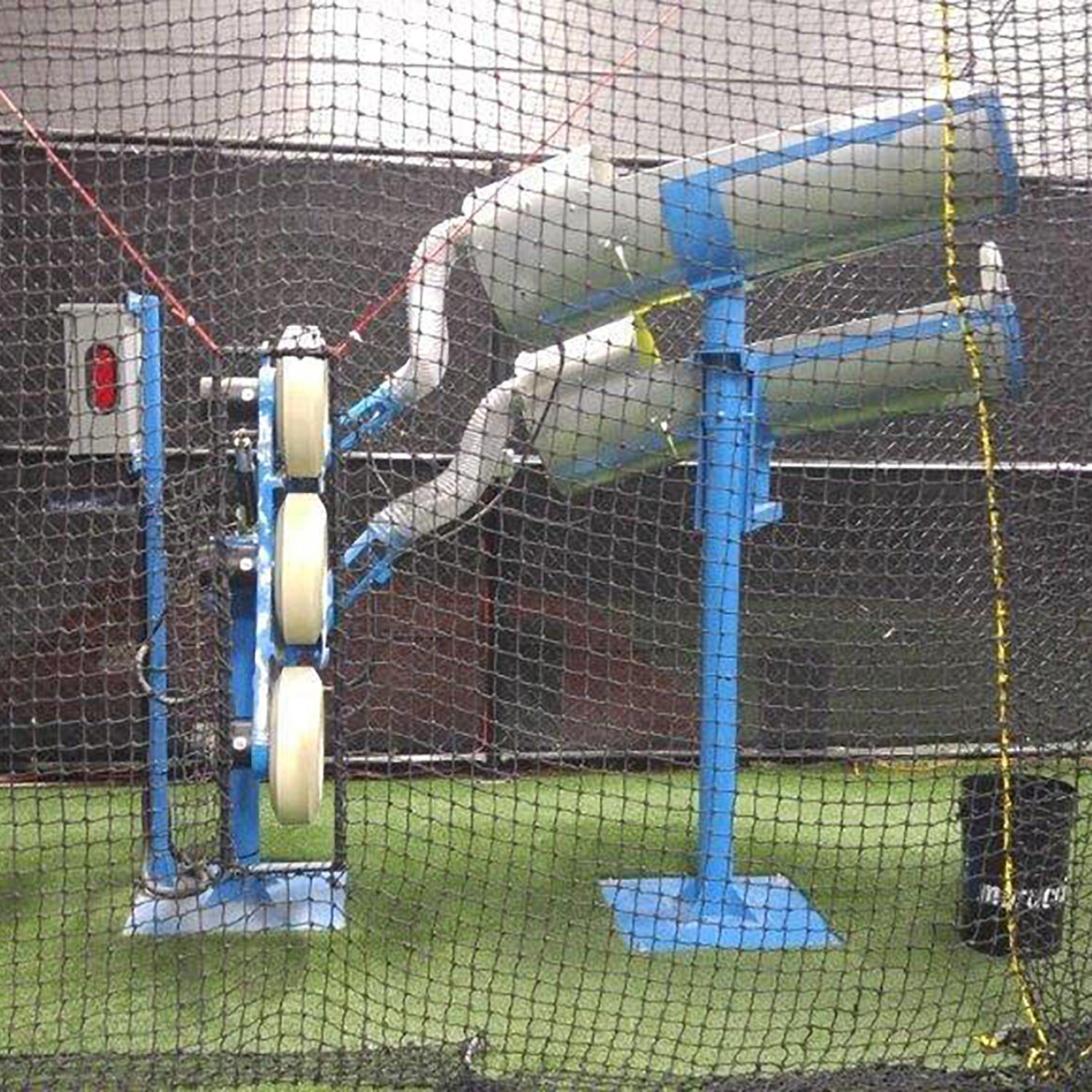

The UT3020 can be used with manually fed hoppers or a fully automated retrieval system:

The 8-speed UT3000 Ultimate Trainer pitching machines have four speeds of baseball pitches and four speeds of softball pitches (including slow pitch) available in every station.

Originally, batting cages used quarters and then tokens. Eventually, swipe and tap cards replaced these as a better way to control the cash sales. Now, Amusement Products in collaboration with Select Pi are introducing a cloud-based purchasing system. There are two methods you can choose from for your new cage.

Our Select Pi system is less expensive and more efficient than the magnetic stripe or RFID tap card system.

CLICK TO LEARN MORE ABOUT OUR CLOUD-BASED PURCHASING SYSTEM

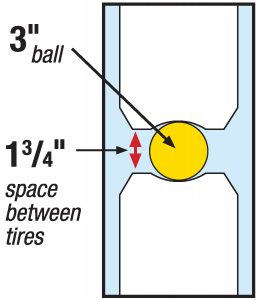

Why do we use air-filled tires?

Why do we use air-filled tires?

As the illustration shows, air-filled tires conform to the ball as it is projected from the machine. Unlike other pitching machines, the use of this type tire continues to mold to balls that have worn down from normal usage, assuring consistent and accurate pitches throughout the life of the tires.

Range-Pro Outdoor Batting Cages

Amusement Products outdoor batting cage “pup tent” design provides the largest hitting area for the least amount of initial cost. This exclusive design was developed to decrease the initial investment while creating a more weather resistant cage. Snow loads and wind loads are more successfully accommodated and damage is avoided by this unique design. In addition, we have added a logo machine roof to reduce sun and element exposure while at the same time advertising and decorating the cage.

Range-Pro Indoor Batting Cages

We build two basic styles of indoor batting cages and Amusement Products has successful operators in both types. The selection of which style cage fits your needs best is a combination of budget and operational ease. The least expensive method is also the hardest to operate. The automated cages are more expensive initially, but pay for themselves in labor saving in a couple of years. Here is a brief summary of each style cage:

1. “Built-to-Fit” Automated Indoor Cage

This cage is fully automated with a retrieval system that separates baseballs from softballs and reloads them into the machines. It requires a sloped floor to get the balls to the pick up point. The sloping of the floor can be done in wood for rented space and in concrete for owned or new buildings. When we use wood, the floors are also covered in carpet to dampen the sound. This is the closest style of cage to outdoor cages and has the best hitting experience. Amusement Products will custom design the cage to fit in your available space.

2. Free-Standing Indoor Cage

This cage uses hopper-fed machines anchor bolted to the existing concrete floor. Since the floor is flat, this is the least expensive cage to start with and the most expensive to operate. It requires the balls to be picked up by hand and sorted manually. Like the “Built to Fit” cage above, the net is attached to the walls and suspended from the existing ceiling. The hoppers hold about 300 balls, which is about an hour’s operation before they need to be refilled. While it increases the operating costs up to 35%, it reduces the initial investment up to 40%. For leased space and small budgets, it is a good way to get started quickly.

Automate Your Batting Cages With The Range-Pro Retrieval System. Savings In Operating Cost Are Automatic.

This state-of-the-art batting cage retrieval system uses a belt conveyor to pick up and separate the balls and feed up to 20 machines on a demand basis. The Range-Pro Retrieval System efficiently feeds directly to the machine or operates in conjunction with a hopper. The system includes a dedicated computer that sends the balls to where they are needed. Balls are metered to all stations needing balls to prevent any station from running out. When all machines are full, the system shuts off automatically.